July 26, 1979

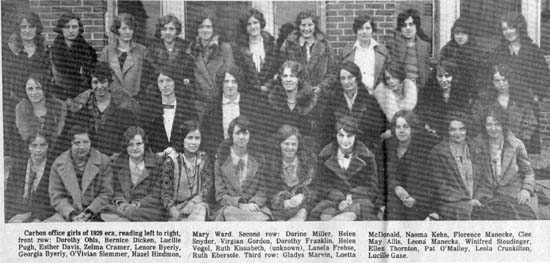

Picture #1 – Carbon office girls of 1929 era, reading left to right, front row: Dorothy Ohls, Bernice Dicken, Lucille Pugh, Esther Davis, Zelma Cramer, Lenore Byerly, Georgia Byerly, O’Vivian Slemmer, Hazel Hindmon, Mary Ward. Second row: Dorine Miller, Helen Snyder, Virgian Gordon, Dorothy Franklin, Helen Vogel, Ruth Kissabeth, (unknown), Lanela Frehse, Ruth Ebersole. Third row: Gladys Marvin, Luetta McDonald, Naoma Kehn, Florence Manecke, Cleo May Allis, Leona Manecks, Winifred Stoudinger, Ellen Thornton, Pat O’Malley, Leola Crunkilton, Lucille Gase.

Picture #2 – H.A. TREMAINE

Picture #3 – J.B. CROUSE

Picture #4 – GEORGE SHAFFER

Picture #5 – JOSEPH SHAFFER

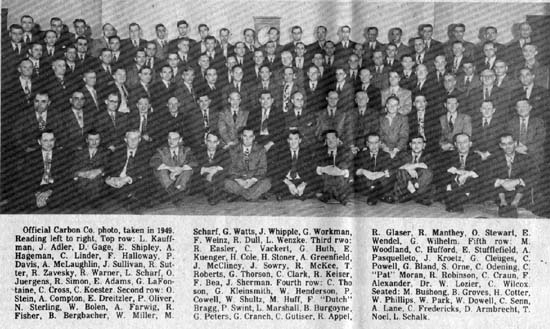

Picture #6 – Official Carbon Co. photo, taken in 1949. Reading left to right, Top row: L. Kauffman, J. Adler, D. Gage, E. Shipley, A. Hageman, C. Linder, F. Halloway, P. Davis, A. McLaughlin, J. Sullivan, R. Sutter, R. Zavesky, R. Warner, L. Scharf, O. Juergens, R. Simon, E. Adams, G. LaFontaine, C. Cross, C. Koester. Second row: O. Stein, A. Compton, E. Dreitzler, P. Oliver, N. Sterling, W. Bolen, A. Farwig, H. Fisher, B. Bergbacher, W. Miller, M. Scharf, G. Watts, J. Whipple, G. Workman, F. Weinz, R. Dull, L. Wenzke. Third row: R. Easler, C. Vackert, G. Huth, E. Kuenger, H. Cole, H. Stoner, A. Greenfield, J. McCliney, J. Sowry, R. McKee, T. Roberts, G. Thorson, C. Clark, R. Keiser, F. Bea, J. Sherman. Fourth row: C. Thoson, G. Kleinsmith, W. Henderson, P. Cowell, W. Shultz, M. Huff, F. “Dutch” Bragg, P. Swint, L. Marshall, B. Burgoyne, G. Peters, G. Cranch, C. Gutiser, R. Appel, R. Glaser, R. Manthey, O. Stewart, E. Wendel, G. Wilhelm. Fifth row: M. Woodland, C. Hufford, E. Stufflefield, A. Pasquelleto, J. Kroetz, G. Cleuges, C. Powell, G. Bland, S. Orne, C. Odening, C. “Pat” Moran, R. Robinson, C. Craun, F. Alexander, Dr. W. Lozier, C. Wilcox. Seated: M. Bushong, R. Groves, H. Cotter, W. Phillips, W. Park, W. Dowell, C. Senn, A. Lane, C. Fredericks, D. Armbrecht, T. Noel, L. Schalk.

Union Carbide Corporation-Carbon Products Division, one of Fostoria’s larger manufacturing plants is 86 years old. It occupies the same site where it started in 1893…and the original building utilized is still in use as part of the sprawling complex on 68 acres, with 18 main buildings which now constitute the facilities.

Some historical accounts published in recent years credit Rawson Crocker as having a part in the organization of the original company. It may well be that he, with the Foster family, provided the land site at the eastern edge of Tiffin Street at Town; and he may have had some financial interest in the company, but other than that it appears from records at my disposal that sole credit for organization of the company was in the hands of J.B. Crouse and H.A. Tremaine, two Clevelanders.

H.A. Tremaine was manager of the Standard Carbon Company of Cleveland before it became part of the National Carbon Company.

Crouse and Tremaine wished to start another carbon plant but were not sure where they wanted to locate. Likely they knew about Fostoria’s mushrooming growth, and the railroad facilities here. They also were investigating sever- al other towns, one of which was Ashtabula, according to Fostorian Esther Shaffer, whose father Joseph W. and Uncle George E. Shaffer had an important part in setting up the original factory in Fostoria.

SHAFFER BROTHERS INVESTIGATED FOSTORIA

The two Shaffer brothers, along with an older brother Bertholdt, had moved to Cleveland from Girard, Penn., where they were orphaned at an early age. In Cleveland, they became friends of Tremaine. When Tremaine was trying to decide where to locate his new carbon plant he sent Joseph and George to all of the possible sites to investigate and make report.

In the final selection, Fostoria with its railroads won out over the other towns and so in 1893, the two Cleveland industrialists organized Crouse- Tremaine Carbon Company. The new plant was a welcome addition to Fostoria since the glass industry here was on the wane, and the new plant provided diversification.

When the Shaffer brothers went back to Cleveland to make their report on Fostoria they never expected to see the town again, according to Esther. However, when the new factory was in the planning stages, Crouse and Tremaine decided to send the brothers back here to oversee the building of it. George, the older brother was put in charge. Joseph, who had been studying the new power, electricity, was to supervise the power and lighting aspects.

“JULIET” OFTEN CAUSED PROBLEMS

To develop electricity for the new plant it was necessary to install a steam dynamo, and Esther recalls that it was later nicknamed “Juliet.” After the new plant was completed and the Shaffer brothers decided to stay in Fostoria and work there, she relates, “One of my first recollections is the telephone ringing in the middle of the night with the message that “Juliet” was ‘down,’ and my father (Joseph) would hurry down the (Nickle Plate) railroad tracks to the factory. When ‘Juliet’ wouldn’t work, no one worked.”

Once the plant was completed it became a problem and a challenge to find people who would work in the “soot factory” as it was often referred to…a circumstance Crouse and Tremaine hadn’t anticipated. Native Fostorians didn’t want to work there. So the Shaffer brothers were enlisted to recruit workers in Fostoria, where they weren’t too successful. They went to their old neighborhood in Pennsylvania, also Cleveland, and finally hired enough to get the new plant into production.

GEORGE SHAFFER FIRST SUPERINTENDENT

By then the Shaffer brothers had decided to stay in Fostoria. George was made superintendent, a position he kept until his death in 1920. Joseph was in charge of all electrical and power needs, and he stayed with the company until citywide power became available, at which time he started a plumbing and electrical contracting business here. However, when the National Carbon Co., Cleveland, successor to Crouse-Tremaine Carbon Company, built their new factory in Clarksburg, West Virginia, they again called on Joseph Shaffer to install the complete electrical system.

In addition to the original founders Crouse and Tremaine, the records indicate that J. Robert Crouse, son of J.B., also B.G. Tremaine made important contributions to the early success of the new carbon plant here.

A critical moment came to the Crouse-Tremaine Carbon Company in 1898 when a fire destroyed all of the mill and mix department and part of the molding and forcing department. The next day H.A. Tremaine took a courageous step. He called the entire staff together and told them that the plant was finished un- less they were willing to work without pay for several weeks while the burned portions of the plant were rebuilt. If they would, he promised, the company would repay them when the factory had filled enough orders to make up their back pay. The old historical record says “they cheered him on, and the fac- tory was rebuilt.”

In 1906, Crouse and Tremaine transferred their holdings in the local plant to the National Carbon Co. of Cleveland, and eventually it became a part of the Union Carbide Corporation.

FIFTY PEOPLE INITIALLY EMPLOYED

Initially, the local plant had a capacity for 50 employees and were able to finish 50,000 carbons daily. Today, 86 years later, the employment is approximately 650.

When the plant started, the main product was carbon rods, used in street lamps. Through the years the product line has expanded until today there are over 900 items produced in the Fostoria plant…some being in small quantities, others, like midget electrodes for flashlight batteries amounting to one-half billion. Arc carbons, gouging and welding carbons, activated carbon, carbon brushes, spectroscopic products and a large variety of specialty pro- ducts round out the line.

By 1928, at which time the Fostoria plant was already a part of the Union Carbide Corporation, it had grown from its small beginning to a major production unit.

ESTHER SHAFFER TELLS HUMOROUS INCIDENT

Esther Shaffer remembers many things…some from personal experience and others as related by her father and uncle in connection with the early carbon plant.

According to her, her uncle George, who was a man of talent in personnel matters, needed all his skill to preserve harmony in the factory when the Cleve- land owners started to send in new, inexperienced Massachusetts Institute of Technology (M.I.T.) graduates to advise and oversee operations.

“They were well-trained in their field, but knew nothing about making carbons. They were from wealthy families with cultured backgrounds, and considered the Fostoria workers stupid and uncouth,” according to Esther.

A humorous incident related by Esther went like this, “One day some workmen were trying to repair a broken-down machine, and the easterners kept getting in the way, and asking all sorts of questions, like, ‘Didn’t it give you any warning?”

“Yes, it did,” answered the workman, “it stood up on its hind legs and said, bow! bow! wow!”

Finally, one of the college men, Mr. Wiswall, solved the problem. He reported back to Cleveland that the M.I.T. men were a disturbing factor, and that more carbons would be manufactured if the college boys stayed in Massachusetts.

As the years passed, and the plant grew, the personnel problems apparently were solved and many college graduates and technicians came to Fostoria from other Union Carbide plants and became valuable citizens here. Some remained, while others were transferred to other plants.

REMEMBER THESE?

Readers may remember some of the following incomplete list of names of people who were employed in various departments of the Carbon Products Division in past years, other than those accompanying the photos:

A.W. Hosig, R.C. Brown, Paul Paine, Keen Van Curan, William Keir, R.W. Merrill, Fred G. Roberts, Harry Mumma, Paul Cooper, Fielder Israel, Ad- die Brombley, George C. Wells, Ed Covrett, John Twining, Carl Stollenmeyer, Richard J. Fountain, Boy Halderman, C.K. Conklin.

W.H. Feathers, Luther J. Roy, Joe Sullivan, Jack Harris, “Bus” McClung, Clyde Medford, James Shane, Esther Chance, Dwight Waite, Walter Henderson, Earl Snyder, Adger Johnson, Howard Degan, Joy Shuman, Wilson Park, Pat Keller, Ray Cole, Henry Riggle, Gerald Shiebley.

EARLY EMPLOYEES

Esther Shaffer, and her older brother George, a retired Toledo teacher, com- piled the following list of names of some of the employees at the carbon plant back in the early days:

Charles Allison, Jack Cummings (father of Ralph), Phil Bohyer (father of Kenny), Charles “Hocker” Vance, John McNally (father of Ella, a one-time society editor for Fostoria Daily Review), the Shaffer family…George, Joseph, Pat, Clair, Mark.

Frank Adams, Orrin Pearce, Forrest Jaynes (later started a nursery and green- house in Painesville), Jay McCracken, John Wise, J.C. Rhodes, (English adventurer and father of Gertrude King, donor to Heidelberg music department).

A.C. Downs, (the first of the M.I.T. people), James Housel, Barney Nolan, and Andrew Fitzsimmons (brought to Fostoria by a church group from Cleveland to give city kids a chance to sample small town life. They liked it and stayed).

Earl Snyder (he probably worked longer than any other of the early employees…father of Fostorian Charles “Bus” Snyder). A Mr. Farrar, (he had been in theatricals, and sang from the Mikado as he worked. Finally returned to Cleveland).

The two early office girls were Elizabeth Thurber, related to James Thurber, the writer, and Gail Sells…both were fine musicians. Those whose first names cannot be remembered were a Mr. Henry in the plating department; Mr. Ensminger, an executive; and a Mr. Kovachitz.

The decision of Crouse and Tremaine to locate their plant in here in 1893 was a good one for Fostoria…any way it is viewed.