December 13, 1977

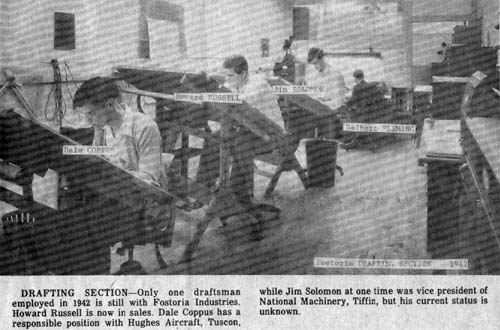

Picture #1 – Drafting Section – Only one draftsman employed in 1942 is still with Fostoria Industries. Howard Russell is now in sales. Dale Coppus has a responsible position with Hughes Aircraft, Tucson, while Jim Solomon at one time was vice president of National Machinery, Tiffin, but his current status is unknown.

Picture #2 (missing) – Fostoria Pressed Steel started in the building above, originally the Seneca White lime Co.

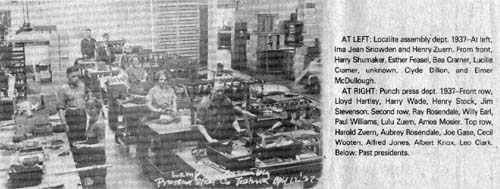

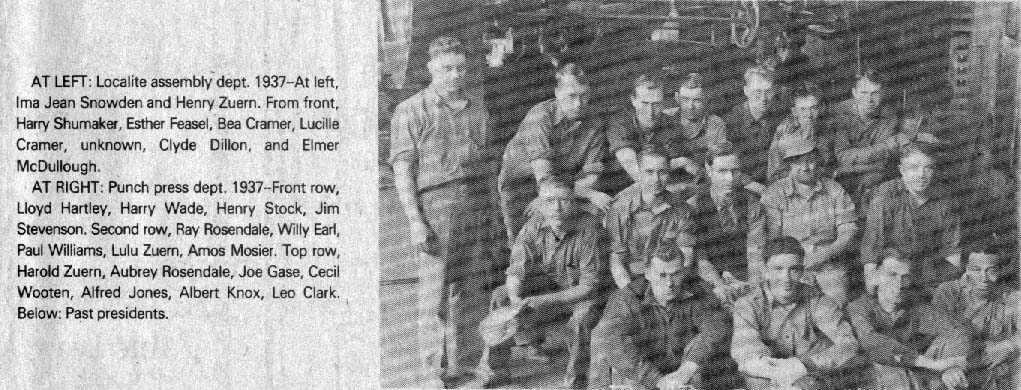

Picture #3 – Localite assembly dept. – 1937. At left, Ima Jean Snowden and Henry Zuern. From front, Harry Shumaker, Esther Feasel, Bea Cramer, Lucille Cramer, unknown, Clyde Dillon, and Elmer McDullough.

Picture #4 – Punch Press dept. 1937 – Front row: Lloyd Hartley, Harry Wade, Henry Stock, Jim Stevenson. Second row: Ray Rosendale, Willy Earl, Paul Williams, Lulu Zuern, Amos Mosier. Top row: Harold Zuern, Aubrey Rosendale, Joe Gase, Cecil Wooten, Alfred Jones, Albert KnoX, Leo Clark,

Picture #5-9 – Past presidents

EDITOR’S NOTE: Today’s Potluck story, because of the length, and the many interesting photos that are available pertaining to it, is divided into two segments. Second segment will appear in two weeks.

Fostoria Industries, the local manufacturer that started as Fostoria Pressed Steel Company 60 years ago, is celebrating its Diamond Jubilee this year.

Like many other manufacturing plants in Fostoria, it was started and nourished through the efforts of local citizens who had dreams for its success…and by planning and hard work for many years saw it happen.

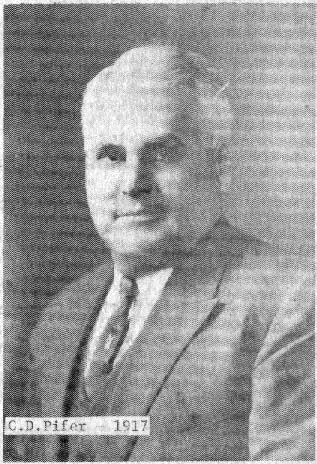

The company traces its origin back to April 2, 1917, when articles of incorporation were signed by W.O. Allen, C.D. Pifer, Henry Rothrock, E.C. Wolfe and George E. Schroth…all local people except Schroth who was from Tiffin. The charter was issued by the State of Ohio April 23, 1917.

It was approximately 20 years later…after many near failures, and disappointments, and changes in product lines a number of times…that the company heads found the right combination and things started to click.

In March 1941, I joined the company as manager of sales promotion, after being employed at The Fostoria Daily Review for nearly 20 years. It seemed like a glamorous place to work where opportunity abounded. Little did I know about the dire curcumstances the company had experienced.

It was not until approximately 1965 when R.J. Carter was writing the company history that I learned the facts. At that time, he asked me to read his compilation. Now 12 years later, rereading the history again, I am reminded that success comes only from hard work, consecration and being on the scene at the right time.

The formation of the company was promoted primarily by interests identified with The Allen Motor Company in Fostoria, for the purpose of making sheet metal parts…primarily fenders, engine hoods, gas tanks and dust sheilds… to be sued by Allen Motor.

Two living area residents are probably the oldest exemployees of The Fostoria Pressed Steel. They are Brooks Moore of Arcadia and Clayton Lee, Columbus Avenue, Fostoria.

Moore was a sheet metal layout man back in 1917-1918 when FPS was making parts for automobile manufacturers. He remembers making parts for the Allen Car.

Lee, 88, worked in the fender department when the demand for automotive parts was booming, and continued his employment for five years.

When The Allen Motor Company moved to Columbus Ohio in 1918 it left a void in The Fostoria Pressed Steel production until they became reestablished in their Columbus facility. This was cause for real concern and so additional stock was issued by the new company to Cruikshank, J.F. Freese, M.A. Thomas and others, along with E.J. Carter of Fremont (father of R.J. Carter) purchased the stock and solved the financial difficulties for awhile.

Automobile manufacturers were springing up all over, and eventually The Fostoria Pressed Steel produced sheet metal parts for Maibohn Motor Car Co., Sandusky; The Economy Motor Car Co. whose name was changed to The Vogue Motor Car Co., Tiffin; and The Seneca Motor Car Co., Fostoria.

However, there were many times during the early history of the company that short-term loans had to be negotiated to meet the payroll; and the written hostory even reveals that everyone took a cut in wages one time to weather the financial storm.

During the company’s early history a variety of products were offered for sale, but eventually eliminated for various reasons, but primarily because of low sales volume since the company’s marketing structure was not suitable for the products. Some of those products were: Titeseal, camp stoves and luggage carriers for cars.

A product which was very good for awhile was automobile fenders. The large number of automobiles manufactured then created a demand for replacement fenders, and the car manufacturers could not supply them.

In 1934 Fostoria Pressed Steel offered 339 different fender models for Buick, Chrysler, Chevrolet, DeSoto, Oakland, Oldsmobile, Plymouth, Pontiac, Studebaker, Whippet-Willys. And, fenders for earlier cars were also available on special order. In their day, fender’s made the city of Fostoria’s well known as Fostoria glassware.

In 1942 The Fostoria Pressed Steel celebrated its 25th Anniversary…and everything seemed rosier than ever…finances, production, sales and an organization that was geared to meet the challenge of the economy and the need for war materials.

The localized lighting products called LOCALITES developed in 1935, were being widely accepted throughout industry.

The fender business was being phased out because of the high cost for dies, and because of the curtailment of steel for non-essential products related to the war effort. However, a filtering device for use on grinding and honing machines was now in the product line and sales were good because of the war.

Infrared equipment for paint drying and for other industrial heat processing jobs had been developed by the company in 1939 and was just in time to help industry with their war production schedules.

Today…during its Diamond Jubilee…with the company’s manufacturing facilities relocated in a new, modern plant…sales of all products are at an all time high.

Between 1942 and 1967 when the company celebrated its 50th Anniversary, more changes in product lines, company name, personnel took place, but localized lighting fixtures and infrared equipment dominated the sales picture.

The company…now known as Fostoria Industries…is a subsidiary of TPI, Corportation with headquarters in Johnson City, Tennessee.

The infrared ovens which the company manufacturers are used for a wide variety of heating applications throughout industry…baking, drying, preheating, dehydration, curing…in factories where metal, wood, fabric, food, electronic, plastic, paper chemical products are produced.

Other infrared devices are produced which are used for heating people, offices, and buildings where it is more economical to use them than conventional heating systems.

Complementing the infrared equipment line, the company also designs and manufacturers control devices which are essential for controlling infrared heat. Basically, the control devices in appearance are similar to switch- control panelboards, but much more sophisticated…actually operating in computer-like fashion, to produce exacting heating temperatures.

Localites, the localized lighting line of equipment which is manufactured by the company, are widely used throughout industry to aid workers to see easily and accurately the tasks they perform. Localized lighting concentrates the light on the specific work area, reduces the amount of light needed for general work area, and thus saves electrical energy…of great importance in today’s energy crunch.

Many Fostorians are not aware that Fostoria Industries is the leader in the design, manufacture, application and sale of infrared control devices and localized lighting equipment on a world-wide basis.

It is imperative to include in this story a tribute to the people, other than the original founders and stockholders who contributed so greatly to the company’s success.

Lester J. Tyler started working for the company April 17, 1917, at the time of its inception and continued until his retirement in 1967, a period of 50 years.

Russell J. Carter joined the company July 1, 1919, served as president and treasurer for many years, and retired with 47 years service.

James Stevenson who retired, Sept. 1972 also had 50 years service.

Others with long service recrods, now retired are: August Blaser* 41 years, Edwin Fraser* 45, Robert Hill* 46, Bessie Steindorf 46, Elmer Cupp 47, Lewis Jeffrey 47, Eddie Massie 41, Joseph Gase 41, Waiter Hartsel 33, Amos Moser* 37, Rudy Renner* 39, Nobel Bell 35, Maude O’Connell 31, Richard McGuire* 32, Harry Sumaker 34, Frank Massie* 28, Burdette Wells* 29, Marie Smith 26, Pha Jones 29, Robert Rojewski* 31, Ray Krupp 30, Bob Hallman* 26, Wilfred Earl 32, Virgil Drupp 28, Paul Krupp 25, Millard Might 26, Jessie McDermid 32. Those marked with asterisk * indicate deceased.

I.J. Barber, during his 16 years with the company made a major contribution in the design and engineering of equipment, and in the sales division.

R.W. Jeffery, retired, served in various sales capacities, also a Technical Director, for a total of 26 years.

R.E. Williams, joined the company in 1940, as a laboratory assistant. Today 37 years later he is vice president and Asst. General Manager.

Paul Williams, deceased, during his many years of association with the company, had an active part in engineering, sales and laboratory work… especially pertaining to infrared. He joined the company in 1937.