April 26, 1979

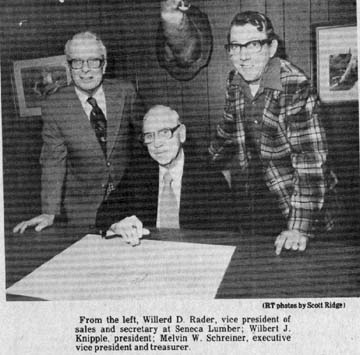

Picture #1 – From the left, Willerd D. Rader, vice president of sales and secretary at Seneca Lumber; Wilbert J. Knipple, president; Melvin W. Shreiner, executive vice president and treasurer.

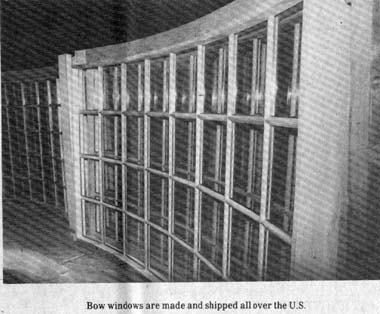

Picture #2 – Bow windows are made and shipped all over the U.S.

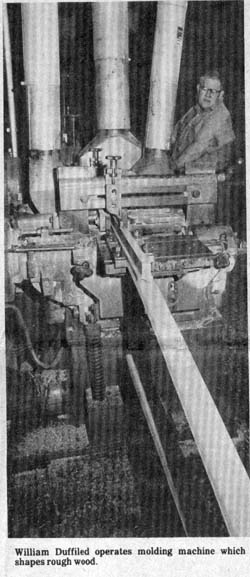

Picture #3 – William Duffield operated molding machine which shapes rough wood

Picture #4 – Circular stairs are made at Seneca Lumber

EDITOR’S NOTE: This is the second in a series of two articles about The Seneca Lumber and Millwork, Inc., Fostoria’s oldest industry.

EXPANDED OPERATION

Under the newly organized company (of 1959) Seneca again expanded their operation, supplying a variety of millwork, including circular staircases and bow windows, and all kinds of custom millwork to meet customers’ specifications. Their products are furnished to churches, schools, nursing homes, condominiums, apartment housing, government buildings, office buildings and residential housing. Seneca’s products are shipped nationwide …every state except Hawaii, and they are working on that.

Readers will be interested to know that many of the new buildings and specialty millwork for Cedar Point was handled by Seneca, including restoration of boats in the riverboat fleet, the elaborate ticket booth for Kiddie Land, Frontier Town, Red Garter Saloon, Pirate Ride, Ice Cream and Candy Shops, Silver Dollar Cafe, the Coliseum on the main midway. Guess your Weight, and buildings along Wilderness Trail.

OHIO CONFERENCE TABLE

Seneca was commissioned by the Commodores of the State of Ohio to assist in refurbishing the governor’s office in Columbus, Ohio in 1973. One of the interesting projects was the manufacture of the conference table for the Cabinet Room. The table, made from walnut, a native Ohio wood, with beautifully matched top and hand-turned legs, is eight feet wide and twenty feet long. It can be separated to make five individual tables. The center table has a white oak inlay hand carved Seal of the State of Ohio, done by Delbert Springer of Van Wert, Ohio.

Accompanying photos show some of Seneca’s ingenuity and skill in designing and manufacturing their extensive line of wood products.

As I have so often said in other articles about local industries, none are better than the people who manage them and the work force which turns out the products. This adage seems to be especially appropriate when applied to Seneca Lumber and Millwork Inc. and all the eras of the company as it progressed from the original company, Fostoria Stave and Barrel, back in 1873.

DESIGN OWN EQUIPMENT

At Seneca, the cutting and shaping of wood pieces often requires modification or complete new designs for the cutting knives in the machinery, and many of those changes are effected within the factory.

The skilled labor required through the years at Seneca has been mostly developed within the work force by special training. In recent years the personnel problem has become increasingly serious at Seneca. Three or four years of training and experience are necessary to develop a good woodworking machine operator, and skilled cabinetmakers develop even more slowly.

There have been many skilled workers who have contributed immensely to the quality of the products manufactured at Seneca through their 106 years. Unfortunately, the records do not list all of them or tell of their particular contributions.

Discussing the manufacturing aspect of the business with Richard Altweis, retired superintendent, I learned about the required skills for the products Seneca makes.

CUSTOM-MADE ITEMS

Examples: the oak doors made for the library for Sisters of St. Francis, Sylvania, Ohio. The casual reader can see beauty in the doors, but the more experienced can see the skill required to do the millwork and final assembly into the finished doors.

Then there’s the communion railing for St. Anthony Church, Columbus Grove, Ohio. The turned spindles alone required skill and long hours.

Consider the conference table for the Governor’s office, shown in still another illustration. Much skill and time went into the ten supporting legs for the table, plus the matched top.

Altweis and other skilled artisans at Seneca contributed greatly to the production of the first bow windows and spiral staircases which the company introduced in about 1960, shown in the illustrations.

The spiral staircases and bow windows are an important part of Seneca’s business today. Both items are made in volume and stocked for prompt shipment all over the U.S.

Anyone who has ever worked with wood, making some rather uncomplicated product “from scratch” knows the thrill when it is finished. That same experience by professionals at Seneca must deliver satisfaction many times greater, which in turn builds skill and perfection.

SKETCHES-DRAWINGS

At Seneca, customers often present only a mental picture of what they want. Then it is up to the engineering department to first transfer the idea to a sketch, and then if correct, to finished drawings for production.

The native timber that once abounded in this area and which supplied Seneca is gone. They now depend on sources in Virginia, West Virginia and the western states…buying it cured in truckload lots and warehoused in indoor storage facilities.

LEADERS OF COMPANY

L.E. Kinn Lucien was the motivating force behind Seneca Lumber when it was in the transition period from the Fostoria Stave and Barrel Works, in the early 1920’s, including the consolidation of the Fraver Mill, and up to the time of his death in 1952. During that time he served continuously as president.

H.J. Blaser “Herm” as he was better known, served as secretary of the company during the time when Kinn was president. At the time of Kinn’s death in 1952 Blaser became president and held that position until the company was sold to Hixon-Peterson.

B.M. Altweis was Kinn’s right hand man for many years, serving as general manager from the early 1920’s up to the time of sale of the company to Hixon-Peterson in 1954.

Wilbert Knipple – Working continuously at one place all of your working years is quite a record, and Knipple made it worthwhile. He started with Seneca in 1923 in the shipping department…then on into retail yard sales. He served as superintendent of the mill when J.H. Maurer was ill. In charge of retail sales up until World War II, when he became expeditor and contract bidder on government jobs. He became general manager under Hixon-Peterson ownership. He also served as treasurer at one time. Knipple became president in 1959. His tenure has now reached 56 years.

Willer Rader – Long tenure and varied experience is Willerd’s record too. He started in 1936 in the receiving department unloading railroad cars. Then he worked in the cutting room and millwork department, and later in retail yard sales. Next he worked in the sales department. During the Hixon- Peterson regime he was assistant general manager under Knipple. Presently he is vice-president and secretary. His work record with Seneca is 43 years.

Melvin W. Schreiner – Presently he is executive vice-president and treasurer. He started in 1951 in the engineering department as a draftsman. He left for a period of three years and upon his return picked up again in engineering, production and sales, and estimators.

J.H. Maurer – “Jake” as he was better known was a valuable employee for 44 years. He started in 1922 and worked until 1957 when he left the company, but rejoined it again in 1959, continuing until 1968 when he retired. His contribution at Seneca was in engineering and as superintendent. He also served as vice-president and treasurer at one time, and as chief estimator. He is now deceased.

Richard Altweis – He started as a truck driver in 1934, but his talents led him into cabinet making and millwork, where he finally became superintendent. He was one of the incorporators of the reorganized company in 1959. He retired in 1975 after 41 years of continuous service.

Otto Omlor – Omlor was an employee with 36 years of continuous service. He started in 1935 in retail yard sales, and then advanced into millwork. He was one of those who was part of the reorganized company in 1959, serving as secretary, and on the Board of Directors. He retired in 1917. He is now deceased.

Harold Musgrave – He is the present superintendent, having joined the company upon the retirement of Richard Altweis in 1975.