August 23, 1978

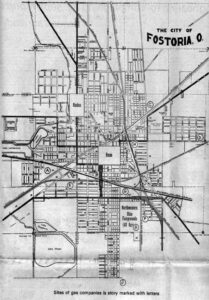

Picture #1 – Sites of gas companies is story marked with letters (map)

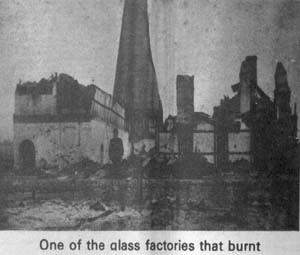

Picture #2 – One of the glass factories that burnt

The glass industry, like all others is always alert to the most economical way to manufacture its products. So back in the 1880’s when an abundance of gas in this area became known, and it was offered free to any industry that wanted to settle here, the glass industry instantly took advantage of the offer. It was a bonanza for them, since they needed large quantities of fuel to melt and fuse the basic ingredients…silicia, sand, soda ash and limestone…that went into their products.

In no time the free offer attracted glass manufacturers from distant points, and also induced local interest to setup factories, 1887 was the year when the first of 12 glass factories started operating here. The accompanying map shows how glass factories were soon scattered all over Fostoria. The following list provides a condensed historical account of each. (The letter suffixes indicate locations in circles on accompanying map).

THE FOSTORIA GLASS COMPANY

(A) Founded in 1887 around a nucleus of experienced glassmakers and workmen from eastern and southeastern Ohio where the glass industry was already active and fostered by businessmen in Fostoria, Charles Foster being one of them.

The plant was located on South Vine Street where Seneca Wire is now. It manufactured a variety of tableware which became famous…and the name Fostoria is still prestigious in the industry and among buyers of fine glassware.

The company continued manufacturing in Fostoria until 1892, when they foresaw the day when free gas would no longer be available and their operating costs would increase substantially. At that time the administrative personnel, mould makers and skilled workers moved to Moundsville, W. Virginia, and set up a plant where fuel was plentiful and cheaper. The factory still exists there and they continue to use the name Fostoria.

THE SENECA GLASS COMPANY

(A) Immediately after The Fostoria Glass Co. left this city, another group of glass makers organized The Seneca Glass Co. and took over the plant that had been occupied by The Fostoria Glass Co.

The Seneca Glass Company produced glass, tableware, including pitchers, tumblers, goblets, wine glasses, soda tumblers.

The company prospered until 1896, at which time they moved to Morgantown, W. Virginia, where they are still located.

MAMBOURG GLASS CO.

(B) This glass factory is another one of those that located here in 1887.

They produced window glass in a new plant constructed for them south of town, west of the Hocking Valley Railroad, (now Chessie System). In later years Bersted Mfg. Co. occupied the building. Copeland Refrigeration Co. is now there.

A Mr. Mambourg was the founder. He was a Belgian, and imported the workers from there.

The factory continued operating until 1894, when it closed.

BUTTLER GLASS COMPANY

(C) One reference source placed the location of this glass factory at the present site of the Fostoria Concrete Block plant on Sandusky Street, but another says it was across from the Sandusky Street school.

The plant was named after William Buttler who was one of the skilled glass- workers and credited with inventing some processes and machinery.

They manufactured tableware. Production started in 1888 and continued until 1889 when the factory was destroyed by fire.

FOSTORIA NOVELTY GLASS CO.

(C) After Buttler Glass Co. burned down, local businessmen reorganized and established a new factory. They produced glass tumblers in it until 1895 when the factory was demolished by fire.

THE NICKEL PLATE GLASS CO.

(D) This glass factory was established here in 1888 by Wheeling, W. Va. people. They manufactured blown goblets, milk glass, cranberry glass, and all kinds of tableware and lamps.

The location was on the north side of McDougal Street, just west of the Nickel Plate Railroad.

In 1891 this glass factory became part of the United States Glass Co.

In 1895, the factory was destroyed by fire. Efforts were made to reorganize and rebuild but they were not successful.

FOSTORIA LAMP AND SHADE CO.

(E) As the company name indicates, they produced lamps and shades to replace the silk and textile shades which had been in common use.

The factory location was south of the Nickel Plate Railroad, on the present site of Ohio Farmers Grain and Supply. The factory as completed in 1890.

Pittsburgh interests as well as Fostorians were responsible for the organization and location of the plant here. In 1894, the business was sold to Consolidated Lamp and Shade Co.

In 1895, the factory burned and all or the management and skilled workers moved to Corapolis, Pa., to start another factory.

THE CALCINE GLASS CO.

(F) This was another window glass factory, organized in 1888, but did not start production until 1890.

The location of the factory was east of The Hocking Valley Railroad, north of the Mambourg Glass co. Production continued until 1894, when apparently financial problems caused them to cease operation.

THE CROCKER GLASS CO.

(J) This was still another of the glass plants in Fostoria that produced window glass. The location was in the northend of town at intersection of Poplar Street and Zeller Road.

It was formed by Roswell H. Crocker, one of the city’s pioneer families. Historical data indicates it may have started production in 1890, and perhaps closed about the same time as the Calcine Glass Co. in 1894.

FOSTORIA INCANDESCENT LAMP CO AND FOSTORIA GLASS SPECIALTY CO.

(G,B) These two glass factories came into existence primarily through the efforts of J.P. Crouse and H.A. Tremaine, who in earlier years had started the carbon plant in Fostoria, and then later sold it to National Carbon Co., Cleveland.

Because of their business connections in Cleveland, these two astute businessmen saw the potential for manufacturing electric light bulbs and glass tubing.

Two factories were involved in manufacturing…one was on South Poplar Street at the east end of Fourth Street…and the other was the building previously occupied by the Mambourg Co. south of town. The Mambourg location was generally referred to as the “lower” plant and the other the “upper” plant.

Fostoria Incandescent Lamp Co. was started in 1897 and Fostoria Glass Specialty in 1899. By 1910 both plants were successful enough to make them a prize purchase by General Electric Co., Cleveland.

After the purchase by General Electric they expanded the operation to existing plants in Cleveland and other eastern Ohio locations. The “upper” plant discontinued operations in 1914 the “lower” plant in 1920.

FOSTORIA GLASS NOVELTY CO.

(G) When General Electric oved their glass-making operations elsewhere, local businessmen Earl Ash, Ralph Pillars, Mahlon Carr. George Ridgeway, organized Fostoria Glass Novelty Co. and took over one of the “upper” buildings. They were assisted in the manufacturing the sales aspects of the business by others who had been long-time glass workers in eastern and southeastern Ohio, namely George and Harry Edmonds, brothers, who were skilled glassworkers, and Harvey Edmonds, son of George, mould maker, and Walter Edmonds, a nephew, who was a salesman.

The business didn’t last very long…perhaps until 1916 or 1917.

MOSAIC GLASS CO.

(H) Historical accounts indicate this glass factory was organized and financed by people connected with the Nickel Plate Glass Co., who remained in Fostoria when it left town.

It was located in a building on east North Street which later was the location of the Fostoria Ice and Coal Co., and currently is occupied by Schreiner Construction Corp., 410 E. North Street.

The life of this glass factory was short-lived, not more than a couple of years at most. A fire destroyed the plant in 1895.

EUROPEON EMIGRANTS

An interesting aspect of the “Glass Days” was the large numbers of skilled workers who were brought to Fostoria from European countries, where glass- making was already established. They came from Germany, France, Austria, Belgium.

Gordon Gray, in a paper prepared about the “Gas-Glass Days” tells how the foreign influx affected retail salespeople: “The great majority of the foreign glass workers who cam here could not speak English. One of the immigrant’s father who was a clerk in a shoe store at that time, told me how his dad would study French at night in order to be able to wait on his foreign trade”.

During that period Fostoria also had residents from Italy, Greece, Ireland, and perhaps other European countries too, so our town was really an “International” community.

CHILD LABOR PRACTICED

The glass factories, back in those early days, were notorious for hiring child labor, since there was no legislation prohibiting it.

Gordon Gray, in his paper, reported all of the glass factories hired a percentage of boys between the ages of 10 to 16 as part of their work force. They were used to run errands for the skilled workers and to do odd jobs and otherwise assist the adult workers in any way possible.

One of the presidents of Fostoria Glass Co., after it moved to Moundsville, W. Va., related that he started in the shipping and packing room at the age of 12, when it was located in Fostoria. He said he was proud that he came up the “hard way”, and had mastered the art of blowing glass during his apprenticeship.

One of the glass companies built a special dormitory and imported a large number of orphans from the eastern seaboard to fill the labor need.